The broken bottles are crushed in the grinder and filled in the scrap box.

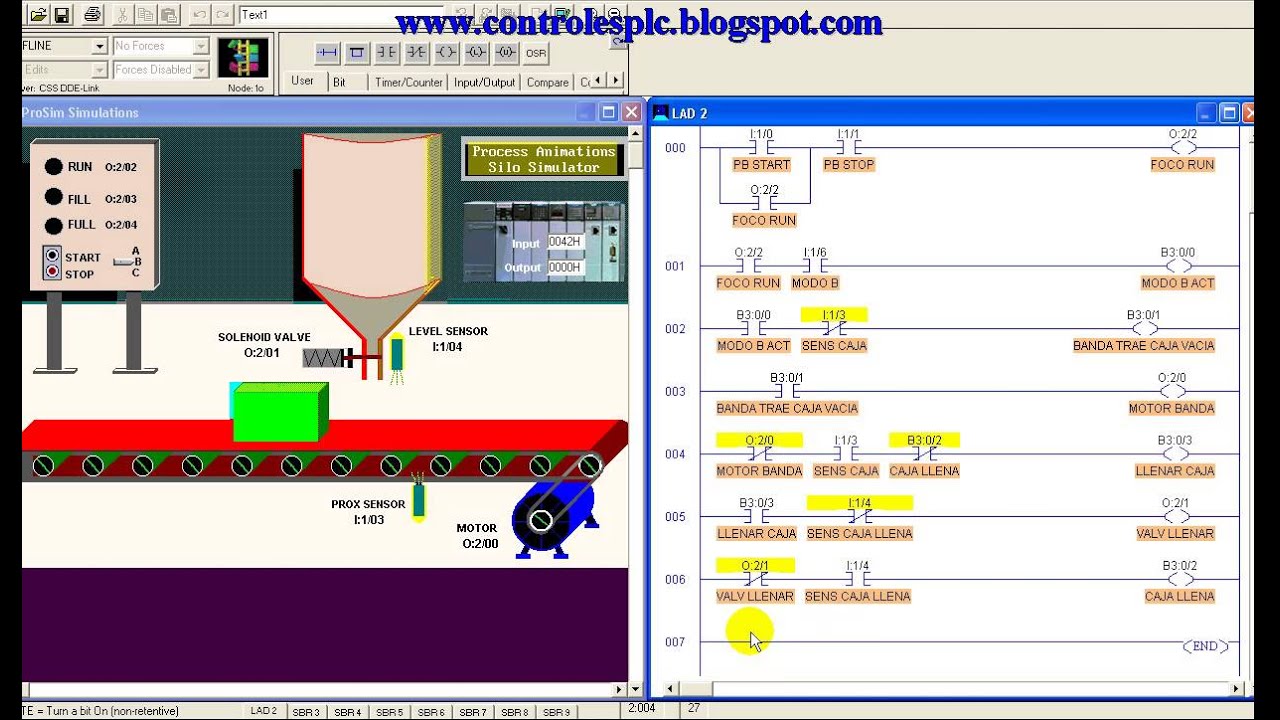

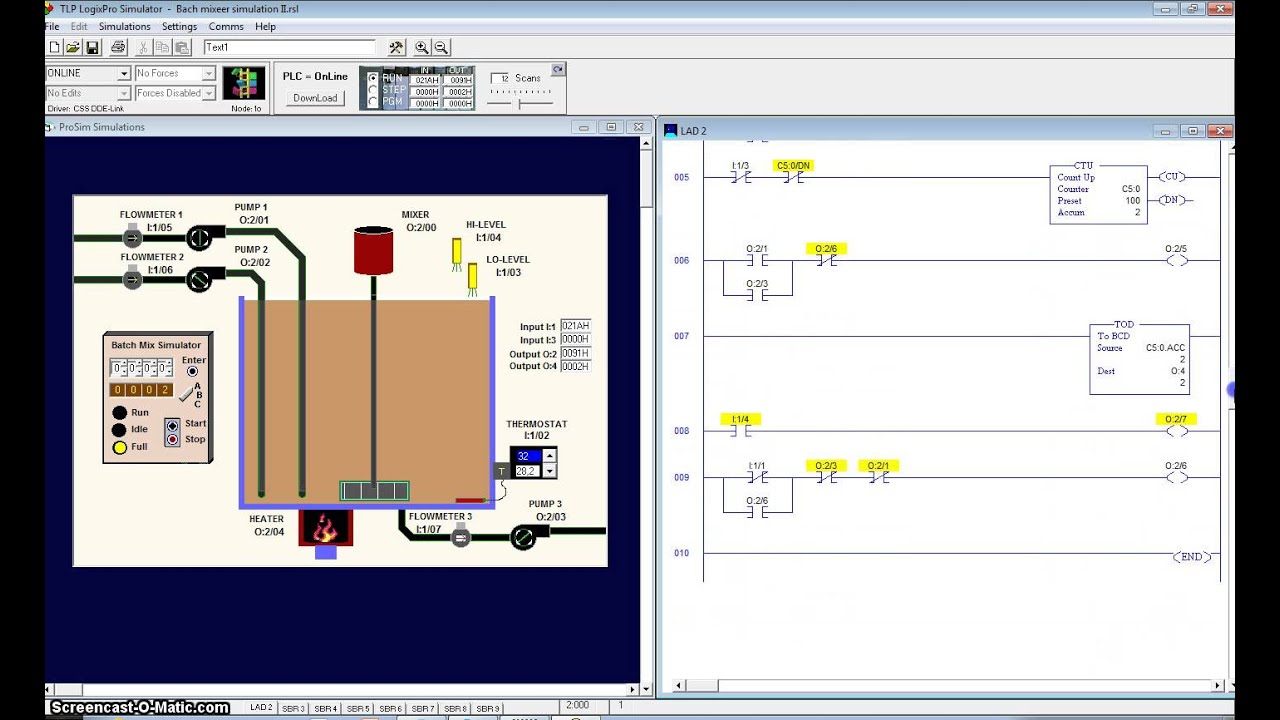

Large bottles are transferred to Divert conveyor through divert gate.Broken bottles are removed from the main conveyor through a scrap gate.Afterward, the liquid is filled in the bottles according to bottle size through a fill tube.There are three sensors that detect bottles, large bottles, and broken bottles respectively.When the Start button is pressed, the conveyor belt starts moving and the bottles shift to the left one by one.LS10 – For controlling the movement of boxesįillers – Bottles are filled up with a large charge for large bottles and small charges for small bottles using a fill tube.ĭisplay – There is a large as well as a small LED display to show results.LS9 – Large bottles are diverted using divert gate with the help of sensor LS9.LS8 – Bottles are discarded using a scrap gate with the help of sensor LS8.LS7 – Bottles are capped using Cap Ram with the help of sensor LS7.LS4 – Bottles are filled using a fill tube with sensor LS4.Switches and Push Buttons – Start, Stop, Run Scrap Conveyor – Broken bottles are discarded through this by using a scrap gate.Divert Conveyor – On it, large bottles are diverted using divert gate.The I/O List in the Bottle Line Simulation is mentioned as follows. The Bottle Line Simulator of Logix Pro 500 simulates an automated production line that produces two different beverages. This makes PLC programming easier to understand. LogixPro mimics Allen Bradley’s RS Logix 500 software.

Bottle Line Simulation in LogixPro Inputs in the Program Outputs in the Program Bottle Line Process PLC Program using LogixPro Simulator

0 kommentar(er)

0 kommentar(er)